Macroscopic materials usually contain numerous cracks, voids, or other structural defects which cause the material to fail at loads way smaller than expected. Their nanoscopic counterparts, in contrast, are virtually defect-free, thus able to withstand higher loads. Integrating the nanoparticles’ mechanical properties into macroscale materials would provide a new niche for applications in a wide range of areas, such as in the aerospace industry. However, assembling nanoparticles into robust macroscale structures still remains a major challenge.

Now, researchers from the Technical University of Hamburg (TUHH) and the Massachusetts Institute of Technology (MIT), in collaboration with the Helmholtz-Zentrum Geesthacht and Bremen University, have achieved the assembly of nanoparticles into strong macrostructures via 3D-printing. “Interestingly, the strength of our 3D-printed materials is in the range of reported values for brick-and-mortar hierarchical composite materials, known for their exceptional mechanical properties,” said Professor Gerold Schneider, head of the Advanced Ceramics department at TUHH.

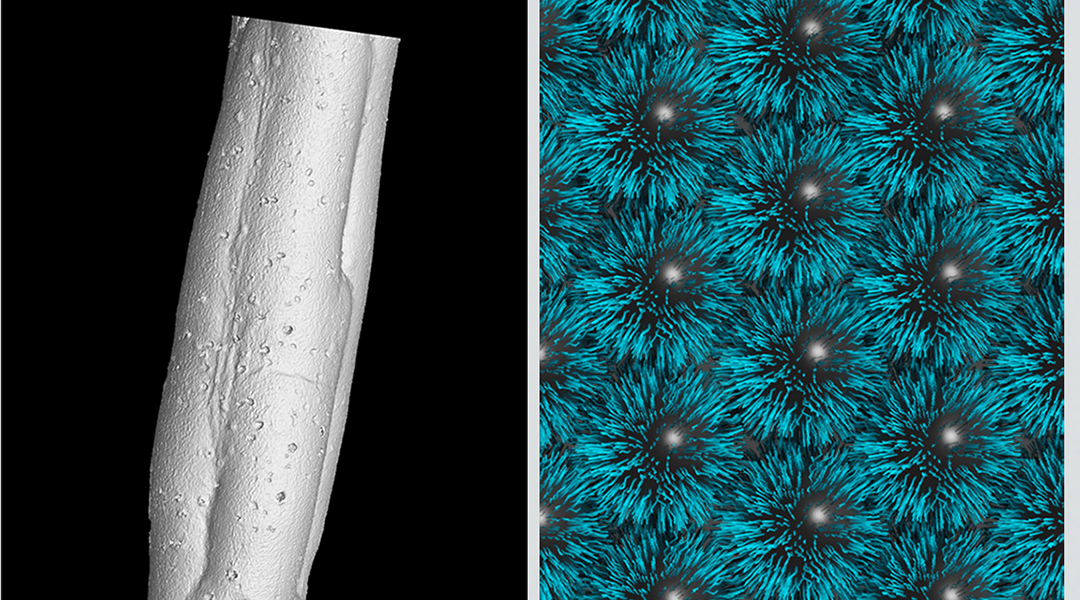

The process was performed using custom-made, benchtop direct-write systems, first developed by Professor John Hart’s team at MIT, and further implemented at TUHH. The team printed free-standing millimetre-scale columns comprising ordered arrangements (supercrystals) of spherical iron oxide nanoparticles (15 nm diameter). The crucial characteristic of these nanoparticles is that their surface is coated with short organic molecules (oleic acid). This surface-functionalization is in fact responsible for the remarkable mechanical properties finally obtained.

First, it allows for a controlled assembly of the nanoparticles into closely packed ordered arrangements (the so-called supercrystals). Second, the organic molecules act as active sites for the additional strengthening of the material. This final strengthening is performed by heat-treatment in an inert atmosphere, which results in the creation of new bonds (through a process called crosslinking) between the organic molecules of adjacent nanoparticles. The crosslinking makes the organic part stiffer, making it resistant to higher loads, similar to the curing process of a common epoxy resin.

“3D printing offers a fast and controllable way to develop new materials. Previously 3D-printed particle-based materials were generally weak since their particles were held together mainly by weak forces (like van der Waals). In our case, the crosslinking step serves as a reinforcement mechanism. This creates a tightly packed network of strong covalently bonded nanoparticles throughout the material,” says Dr. Berta Domènech from TUHH, who coordinated the study.

The team’s next steps aim to acquire more control over the process parameters, expanding the study to other nanoparticle systems, and varying the geometry of the printed structures. “Enhancing the mechanical properties of 3D printed particle macrostructures is a key step towards applications,” says Dr. Alvin Tan from the Hart group at MIT. As a long-term perspective, the authors envisage that this combination of 3D printing and self-assembly will pave the way towards the integration of nanoscale-building blocks into a variety of macroscopic multifunctional materials, ranging from photonic devices to new structural materials.

Reference: Berta Domènech, et al. ‘Strong Macroscale Supercrystalline Structures by 3D Printing Combined with Self‐Assembly of Ceramic Functionalized Nanoparticles.’ Advanced Engineering Materials (2020). DOI: 10.1002/adem.202000352